The shop had spent hours trying to remove the wheel to no avail. They soaked it in rust remover and suggested I take it home and give it some time to loosen up. Otherwise, they would have to take a torch to the wheel, likely destroying the wheel, and definitely requiring a rebuild of the bearings and brakes in that corner of the truck.

I spent the weekend trying various chemicals and mechanical approaches, with no luck. I researched the problem on the internet and did find a device for pulling seized wheels. Unfortunately, it cost $1400 and was sized for bus wheels. I then started designing a smaller scale puller that I could build my self with cheap, easily sourced materials.

My design closely modeled the commercial model. I needed a hollow cap to fit over the hub which would push against the hub and, ultimately, against the truck. I need an arm, chained to the wheel itself, that would pull the wheel away from the truck. Finally, I would need some way of moving the cap and arm apart, thus pulling the wheel off the truck. The patent application for the commercial puller upon which I based mine has some useful diagrams of the concept.

Here are the construction details for my wheel puller:

I constructed the puller out of a couple of lengths of angle steel, and one length of flat plate steel. These had the advantage of being cheap and available from the local home center.

Thanks to my dad, I have a drill press in my shop for making precise holes in the pieces. For this project, I had to drill holes as large as 3/4" to accommodate the long bolts at the heart of this machine.

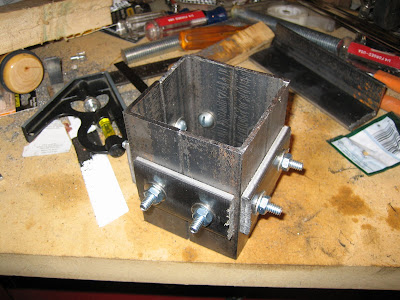

Here is the cap that slips over the hub. It is constructed of four short lengths of angle steel, strapped together with four strips of flat steel.

I cut all this steel using my reciprocating saw fitted with the nicest metal cutting blade I could find. This worked great! Cut through this steel like butta.

Instead of a single large shaft to separate the cap from the arm, I decided on four parallel shafts which could be reasonably tightened with hand tools. In order to get rods thick enough and long enough, I bought a single 36" by 3/4" threaded steel rod. I cut this in to four equal lengths.

Here is the complete cap, on which I have mounted the four threaded rods.

The complete puller mounted to the wheel. Note that the arm is moved away from the cap by tightening the bolts on each rod. The arm is attached to the wheel with high strength chains.

After a bit of tightening, you could feel the tension in the air :-) After a while, there was a satisfying POP!, followed by cheering from Lizz. After a week of construction noise in the basement each night after work, the wheel was off on Saturday morning and had new tires that afternoon.

1 comment:

Genius! I ain't never woulda thunk of something like that...

Post a Comment